Ark Prefab is Global Enterprise

Specializing in providing modular solutions for temporary construction facilities

- years +

History

- +

Sales Regions

- +

Advanced Designs

- +

Employees Internationally

ARK Prefab was established in 2005 and has been developing vigorously for 20 years. The company is currently headquartered in Shanghai, a city with convenient transportation. After decades of development, ARK has many subsidiaries in Hong Kong and mainland China, including Ark Prefab Co. Ltd., Ark Pacific Pty Ltd etc. and has become a leading manufacturer of prefabricated buildings, suppliers and modular building construction contractors. The company currently has three complete product production lines.

Over twenty years of industry experience

ARK Company has experienced the development process from building materials trading, OEM and sales, to independent research and development and factory establishment. Now it has grown into a prefabricated modular building system group integrating R&D, manufacturing, procurement, trade, installation and after-sales service company. ARK, headquartered in Shanghai, an international business center, has cultivated a group of talents with design, manufacturing and quality control capabilities in the field of prefabricated modular building systems over the past 20 years. Taking advantage of the industrial clusters in mainland China, ARK Company has the qualifications for turnkey projects from design, production and processing, packaging and transportation to on-site installation, and has accumulated valuable industry experience.

Efficient and reasonable quality control management SAP ERP

ARK Company adopts the most advanced management platform SAP ERP as the company’s management system. After years of business processing in the field of prefabricated modular buildings, ARK Company has introduced the German SAP ERP management system, which covers finance, procurement, technology, inventory, production, quality control and marketing, etc. to effectively manage and control, coordinate and communicate with various departments of the company.

At ARK, each product spare part has a corresponding material code and is stamped with a unique ID number before shipment. This approach not only minimizes error rates, but also makes it easier to trace product production back to its source.

From light modules to heavy modules to special modules, from temporary housing to permanent buildings, from houses to supporting facilities, ARK’s products form a complete factory-based prefabricated building system. This system covers a variety of building types, providing customers with a wide range of choices and customized services.

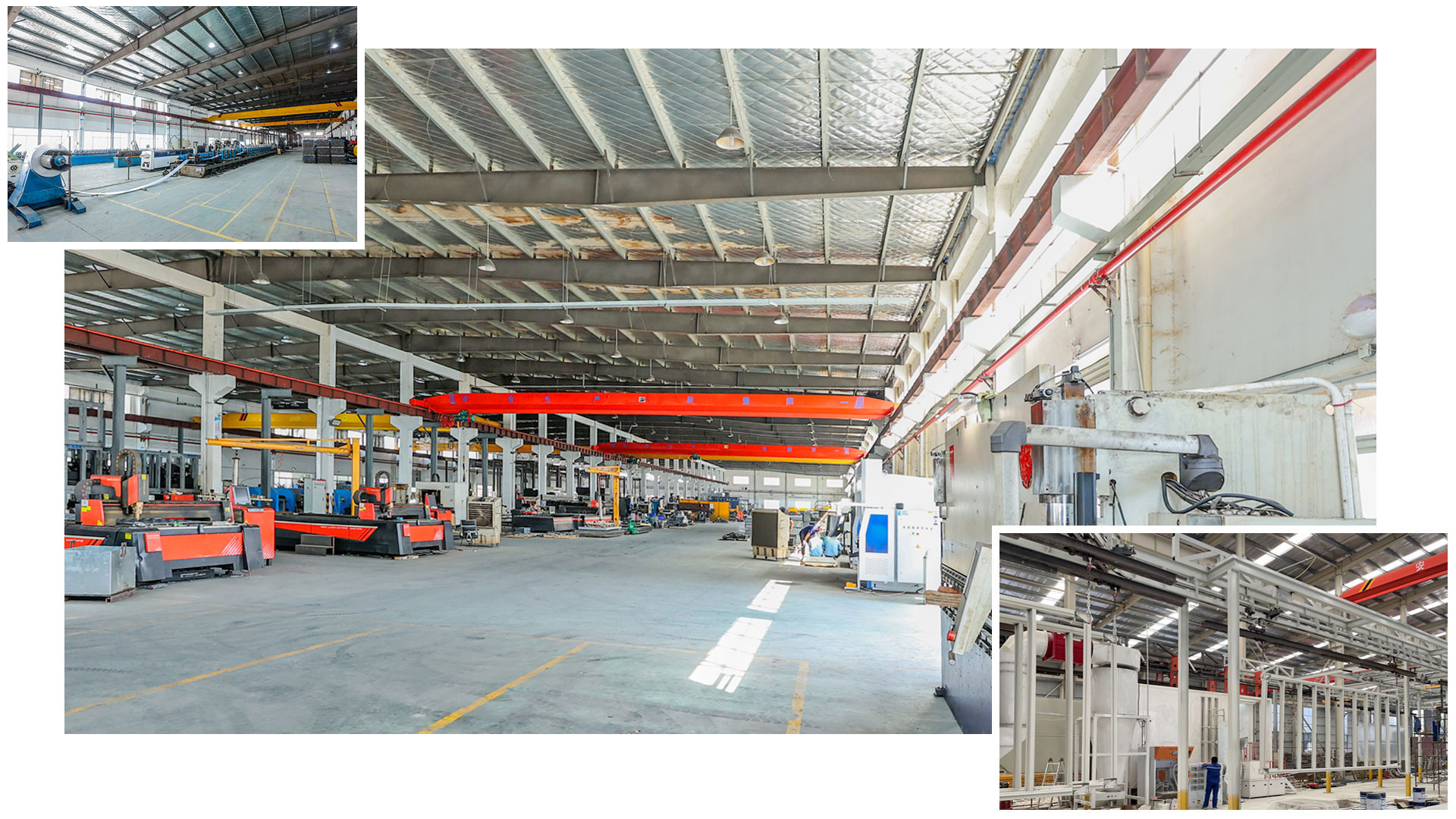

Advanced digital precision production line

ARK has the most advanced Flat-pack II manufacturing facility in the Far East.

1. The robot welding machine accurately welds the corner parts, ensuring that the installation error of the corner parts is no higher than 0.01\1000mm.

2. Advanced laser cutting machines accurately process the cutting of plates, pipe fittings, and related accessories to ensure the accuracy of product dimensions.

3. CNC bending machines can efficiently handle the bending of various components.

4. Pneumatically driven manipulators and fully automatic sandwich panel production lines imported from Italy and other places. The production process strictly follows ISO9001 and ISO14000, which is efficient, time-saving and labor-saving.

5. Light steel forming equipment can easily produce different types of light steel roof trusses matching the modules.

6. Standard fully automatic assembly line paint spraying and drying system.

7. Modular cold-formed steel W70 production line, which gives full play to the characteristics of the material cross-section, making cold-formed steel more economical and reasonable, and can effectively save resources and energy, reduce processing costs, and avoid environmental damage pollute.

8. The flexible coil laser cutting machine is a one-stop processing production line for metal coils from uncoiling, feeding, cutting, and blanking. There is no need for molds and materials are taken on demand, which not only saves materials, but also greatly reduces labor time.

9. Flexible assembly welding line: It helps to quickly switch products of different specifications when changing production. Since these products of different specifications are supported by tooling during production, product assembly accuracy can be guaranteed.

10. Flexible steel structure assembly welding line: products of different specifications can be produced on the assembly line, and product quality and production efficiency can be controlled and guaranteed at the same time.

Annual production capacity

Ark Prefab has become the first-class flatpack solution provider with the flexible production capacity in the Far East. Annual production capacity reaches 480,000 square meters.

Certification

Our products and factory facilities, including TUV-certified management systems, have been accepted by customers around the world. ARK products also passed TUV’s structural testing and were certified as the best modular buildings in Asia.

The ARK module has passed and obtained the CSC shipping container certificate nameplate from the China Classification Society, and can be directly packaged for shipping.

ARK factory has passed EN1090 certification since 2015, and all ARK steel structures are CE approved.

ARK module wall panels have passed the 60-minute fireproof test of BS470 and the 32db sound insulation test of ISO717-1.

Project experience

In addition, ARK has completed multiple EPC/EPCC/EPCM projects for global energy giants such as ExxonMobil in the past 20 years, such as fully functional operating camps Komo Airfield Facilities and OBC. There are also accommodation and office camps provided by Qatar Gas Company. ARK’s projects cover more than 80 countries and regions around the world. Our team has accumulated rich project experience to cope with project design, construction, etc. in different regions.